Enhance Workplace Safety and Efficiency with Custom Engraved Device Covers

for ANY INDUSTRY

Engraved Device Covers – for Industry – Contractors working within Federal Buildings, Hospitals, and Schools, seeking Switch Plates and Outlet Covers tailored to your precise requirements, you need look no further! Seriously, when it comes to Engraved Device Covers, we’re the go to Pros. Do you require Laser Engraved Device Covers capable of withstanding the bustling environments of medical centers, federal buildings, or other professional settings? Laser Engraving Pros by way of Engraving Switch Plates NOW, is your trusted partner.

We’ve only been at this for 134 year, no biggie.

We specialize in providing business owners with professional-grade Engraved Device Covers and Outlet Covers to enhance their workspace branding. Engraved Device Covers play a crucial role in various industries, serving not only aesthetic purposes but also fulfilling essential functional and safety requirements. Let’s delve deeper into the industries that heavily rely on Engraved Device Covers, the rules and regulations governing their use, and the significance of these regulations in ensuring safety and compliance.

Healthcare Industry:

In hospitals and medical facilities, Engraved Device Covers are indispensable for ensuring proper identification of electrical outlets, switches, and other devices. Clear labeling is essential to prevent confusion and facilitate swift action during emergencies. Regulations such as those set forth by the Joint Commission and the National Electrical Code (NEC)mandate the use of standardized labeling and safety protocols to minimize the risk of electrical accidents.

Government Buildings and Institutions:

Federal buildings, government offices, and educational institutions have strict requirements regarding electrical safety and device labeling. Engraved Device Covers for Industry are used extensively to comply with these regulations, ensuring that switches, outlets, and other electrical components are clearly marked and easily identifiable. Compliance with regulations such as the Americans with Disabilities Act (ADA) and building codes is essential to ensure accessibility and safety for all occupants.

Construction Industry:

Construction contractors and building developers often require customized Engraved Device Covers for industry. To meet the specific needs of their projects Our Covers are the Answer! Whether it’s marking switches in commercial buildings. Possibly identifying hazardous materials in industrial facilities, or ensuring compliance with building codes and regulations. Engraved Device Covers are integral to maintaining safety and functionality. Contractors must adhere to industry standards and regulations set by organizations such as the Occupational Safety and Health Administration (OSHA) to ensure workplace safety.

Safety and Compliance Regulations:

Across all industries, Engraved Device Covers must meet stringent safety and compliance standards to ensure reliability and durability. Regulations govern various aspects of Engraved Device Covers, including materials used, labeling requirements, and installation procedures. For example, covers must be made from fire-resistant materials. They must feature permanent markings that withstand wear and tear, and adhere to specific size and visibility requirements. Non-compliance with these regulations can result in fines, penalties, and even legal liability in the event of accidents or injuries.

Advancements in Technology:

With advancements in laser engraving technology and materials science, these Covers have become more versatile, durable, and customizable. Laser engraving allows for precise and intricate designs. Enabling businesses to create intricate covers that align with their branding and aesthetic preferences. Additionally, the use of durable materials such as stainless steel and impact-resistant plastics ensures longevity and resilience in demanding environments.

Order – Engrave – Pack – Ship : All Faster than the Big Guys can get Your First Name!

Engraved Device Covers play a critical role in various industries, ensuring safety, compliance, and functionality in diverse settings. From healthcare facilities to government buildings and construction sites, these covers serve as essential components of electrical systems. They provide clear identification and marking of devices. Compliance with regulations and standards is paramount to maintaining safety and preventing accidents. Underscoring the importance of using high-quality, compliant Engraved Device Covers. With advancements in technology and materials. Businesses can now benefit from customized solutions that meet their specific needs while adhering to industry regulations and safety standards.

Let us Handle those Engraved Device Covers – No Worries We’ve got Experience.

– Metal OR Plastic –

The Real Hard Hitting Question.

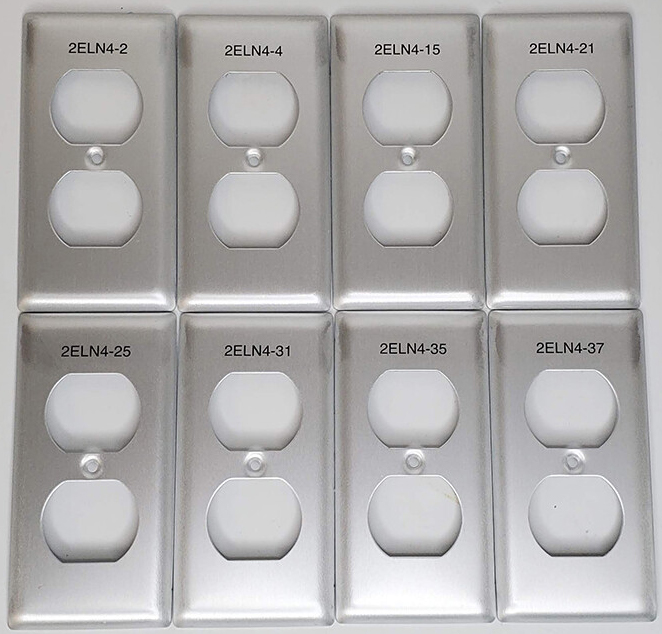

Stainless steel, Aluminum, and Painted Steel are popular materials used in the manufacturing of Engraved Device Covers for Industry. This is due to their durability, corrosion resistance, and aesthetic appeal. Stainless Steel, known for its strength and resistance to rust and corrosion. Its also often chosen for applications requiring high durability and a sleek, modern look. Aluminum, prized for its lightweight nature and excellent conductivity. It is ideal for environments where weight is a concern, such as aerospace and transportation industries.

Stainless – Aluminum – Painted Steel

Painted steel offers the advantage of customization. Allowing covers to be painted in various colors to match interior decor or branding requirements. All while still providing robust protection against wear and tear. Our expertise extends to hospitals needing wall plates for swift and accurate identification of hazardous materials. Federal buildings and government offices requiring switch plates with clear labeling for intricate projects. Construction Contractors seeking to customize switch plates with permanent marks also find their solution with us.

PO’s OK! – NO MINIMUM ORDER – Get a Free Sample

Engraved Device Covers for Industry – All of Them!

Plastic Engraved Device Covers for Industry offer a cost-effective and versatile alternative to metal covers. High-quality plastics such as polycarbonate or ABS are commonly used for their durability and impact resistance. Thus making them suitable for high-traffic areas or environments prone to vandalism. Unbreakable plastic covers provide an extra layer of protection against damage, ensuring longevity and reliability in demanding settings.

Only Thing Faster than our Lead Times – Are the Reorders!

Lutron, a leading manufacturer of lighting control systems, offers a range of plastic Engraved Device Covers for Industry. They’re tailored specifically for their products. These covers are designed to seamlessly integrate with Lutron’s switches and dimmers. By providing a cohesive and aesthetically pleasing solution for lighting control in residential, commercial, and institutional settings. With their commitment to quality and innovation, Lutron sets the standard for excellence in the field of Engraved Device Covers. Offering customers reliable and customizable solutions that meet the highest standards of performance and design also.

We Can Paint Fill ANY Color You Want – No, REALLY!

Engraved Device Covers – Your search ends Here.

Trust our experienced and passionate team of engravers for any project, no matter its scope or complexity! In hospitals and government buildings, we take our craft seriously. But fear not! Our expertise extends beyond these realms; we can engrave and paint-fill any type of Engraved Device Covers you require. We hold ourselves to exacting standards, delivering top-notch engraved Device Cover. They Feature both text and visuals, boasting a smooth, scratch-resistant finish. Plastic Outlet Covers and various other Engraved Device Covers are within our purview. We provide everything necessary to create stunningly beautiful engraved cover plates. That AND complete with expert paint filling that endures for decades.

Switch to Perfection, Engrave Asset Tracking NOW.

Backed by state-of-the-art equipment, unwavering dedication, and years of experience, our skilled team ensures a pristine and precise final product. Moreover, we offer competitive pricing and fast turnaround times. When we say fast, we mean it! Our average turnaround time for engraved and paint-filled Switch Plates and Outlet Covers ranges from 24 hours to seven days. Contingent upon the quantity of outlet plate covers among other factors. Do You Need 1000 Engraved Device Covers completed within a week? No problem, but time is of the essence! No dilly dally. We frequently accommodate rush orders, sparing no effort to fulfill your Device Cover order in record time. Within the realistic confines of natural laws, of course.

We deeply value our customers and strive to meet their needs whenever possible. So, if you seek unparalleled quality, limitless customization options, and lasting durability for your Engraved Device Covers, look no further. We’ve got you covered, quite literally! Plus, not only do we guarantee top-quality products, but our customer service is second to none. Allow us to assist you today and transform your vision into reality! Our Laser Engraving and Paint-Filling Services offer the ideal solution for your custom Electrical Outlet Cover Plate needs.

Do you need Engraved Device Covers?

Got Another Project In Mind?

(800) 482-1553

Monday – Friday – 9:00 am – 5:00 pm