Paint Filling Stainless Plates

Paint filling Stainless Plates in this industrial and manufacturing environments where switches control various machinery, accurate labeling is crucial. Engraving, a tradition dating back to 1891, has evolved to adapt to modern needs. A notable shift is seen from Engraved Device Covers to the innovative realm of Paint Filled Stainless Plates.

Engrave Excellence: Precision for Every Industry, Switch to Laser-Engraved Plates!

In the technology-dominated era, clear and identifiable controls are essential. Laser engraving on stainless steel covers has become a practical solution for professional and personal needs. Laser Engraving Pros, with years of experience and an array of laser machines, transforms stainless steel plates into personalized masterpieces. The process offers customization Paintfilling Stainless Plates with marks ranging from light to dark, deep to superficial.

Proper labeling extends beyond aesthetics; it plays a crucial role in minimizing errors and accidents. Distinctly labeled switches help operators and maintenance personnel easily identify functions, fostering an organized work environment. Compliance with industry regulations and safety standards becomes more achievable with accurately labeled electrical components.

Track the Trend: Illuminate Your Business with Laser-Engraved Switch Plates!

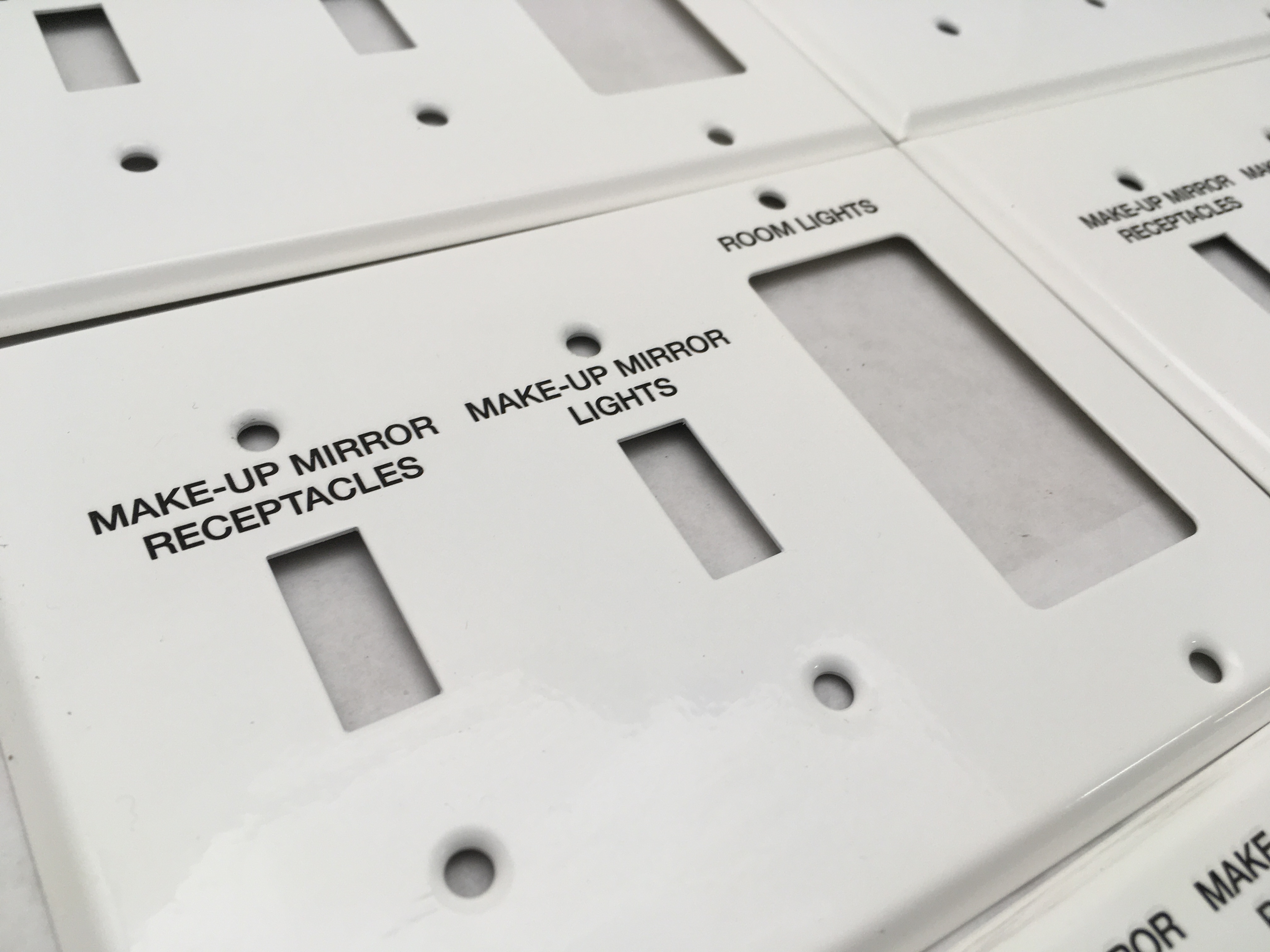

It’s always important to have your client, project manager, or inspector approve a sample wall plate before we engrave and paint-fill. It’s crucial to address character height, font, spacing, and placement on each cover. Fill out a sample request form and let us get to work. We need to know what kind of cover, as well as the color. We need you to provide the data to be engraved, your shipping address, and you can let us do the rest!

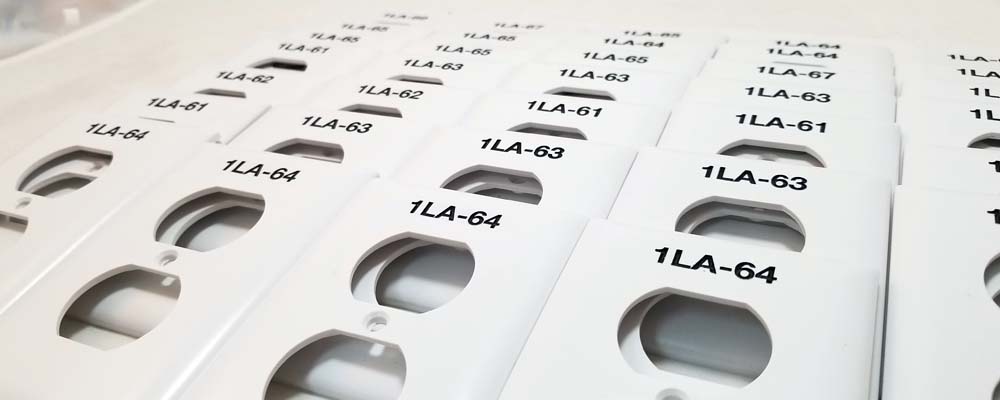

Enhance efficiency in medical and school environments with laser-engraved switchplates for seamless asset tracking

The commitment to precision and creativity is evident in the seamless fusion of technology and artistic expression encapsulated in Paint Filled Stainless Plates. Each plate serves as a unique canvas, combining functionality with visual appeal. This innovative approach represents a dedication to pushing the boundaries of what is achievable in the realm of identification and customization.

Elevate Plate Tracking, Define Critical Data.

The applications of Paint Filled Stainless Plates extend far beyond mere practical concerns. As industries embrace this advanced technology, they not only benefit from efficient and lasting identifications but also contribute to environmental sustainability. The permanence of laser-engraved markings reduces the need for disposable labels, aligning with global efforts to minimize waste.

Custom Plate Engraving, Universal Asset Tracking.

As we move forward, the future promises even more sophisticated solutions in permanent identification through advancements in laser engraving technology. Enhanced speed, increased material compatibility, and additional features are on the horizon, making it imperative for industries to stay informed and adapt to these transformative developments.

In the dynamic landscape of industrial and manufacturing settings, where attention to detail is paramount, the transition to Paint Filled Stainless Plates represents not just a shift but a leap forward into a future where precision, durability, and creativity converge to redefine the way we approach identification and customization challenges. Explore the possibilities today!

Let us take the next Job off your shoulders!

We can engrave, paint fill, and expedite wall plates faster than anyone in the country. Do you need them drop-shipped directly to various job sites? No problem! We can box and pack your wall plates in ANY order by room, floor, or suite. If you need a sample plate created, send us your wall plate info, the data to be engraved on it and your shipping address. Request a sample here. This way, you get truly pristine and perfectly engraved and paint filled cover plates with clean edged lettering.

Simple Ordering – No PO Needed to get started

At the end of the day, paint filled laser engraved switchplates offer an incredibly cost effective way to customize your space without breaking the bank. Whether you need something simple yet classy or something extravagant yet still affordable – this is definitely an option worth considering! Plus, with our wide array of colors available as well as custom options available upon request – there’s no limit to what type of design you can come up with!

Safety Engraved, Organization Perfected: Laser Solutions for Switches and Walls.

Laser engraving on stainless steel plates is preferred for its versatility and precision. Laser Engraving Pros, starting as National Seal Works, has been committed since the 1890s. We cater to diverse needs with a production facility accommodating special requests and deadlines. Whether for individuals or large businesses, every order receives attention to detail and craftsmanship.

“Since 1891 The House Of Good Impressions”

More Than a Century of Thanks!

The uniqueness of our company lies in its engraving prowess and collaboration with clients. A tailored quote based on individual requests, including the option for clients to provide their material for engraving, is part of the seamless process. Shipping, whether items for engraving or finished products, is handled efficiently.

We reflect Laser Engraving Pros’ capabilities, showcasing high-end processing software for accurate data import into engraving systems. Custom-designed equipment for engraving device covers demonstrates efficiency and excellence.

Track Every Detail, Ensure Every Switch: Laser Engraved Plates for Safety Excellence.

Paint filling Stainless Plates including custom wall plates and receptacle plates, offer versatility beyond engraving. We add a layer of customization with paint filling, creating distinctive pieces for any setting.

Order – Create – Ship – Repeat!

The laser engraving process uses high-powered laser beams to etch patterns on materials like stainless steel, metal, nylon, and plastic. Beyond etching, it can paint fill circuit and panel numbers onto the plate’s surface, ensuring legible and enduring identification. Laser engraving surpasses traditional methods in detail and customization, making it ideal for precise identification in various industries.

As technology progresses, laser engraving techniques may evolve further, bringing enhancements in speed, material compatibility, and additional features. Staying informed about these advancements is crucial for industries relying on laser engraving for identification.

Only Thing Faster than our Lead Times – Are the Reorders!

Exploring Our fabrication services reveals extensive capabilities in switch plates, from engraving circuit numbers to paint filling. High-end processing software ensures a seamless transition from concept to product, with clients receiving a proof before production.

The shift from Engraved Device Covers to Paint Filled Stainless Plates signifies a transformative leap in identification and customization. Laser engraving lays the foundation for enduring markings, and paint filling adds aesthetic appeal, making each plate a unique component in various settings.

Efficient Engraving, Punctual Delivery – Where Precision Meets Timeliness, Every Project, Every Time.

This innovative approaches applications extend across industries, addressing practical concerns and environmental considerations. Laser-engraved markings reduce reliance on disposable labels, aligning with sustainability goals. The technology’s efficiency simplifies installations for electricians and enhances project timelines.

The advantages of laser engraving – cost-effectiveness, durability, and efficiency – become evident when considering long-term savings from eliminating periodic label replacements. Laser-engraved identifications ensure a lasting solution in environments with significant wear and tear. Get a quote today!

Options Galore, Hassle No More – Pay with Ease, Every Time.

Electricians and inspectors benefit from laser engraving on Nylon Wall Plates, experiencing simplified installations and clear identifications. The shift from labels to laser engraving into the material streamlines processes and reduces waste. Paint filling Stainless Plates looks so good!

Skip the detours, embrace direct shipping – your package express route to happiness!

Laser Engraving Pro’s cost-effectiveness comes from creating permanent markings, eliminating ongoing expenses for periodic label replacement. The precision and accuracy of laser-engraved markings ensure consistent identification, surpassing traditional methods. The expedited process minimizes the need for manual labor.

As industries evolve, the continued advancement of laser engraving technology promises more sophisticated solutions. Staying informed about these developments is crucial for industries relying on laser engraving for identification.

Paint filling Stainless Plates represents a harmonious blend of precision and creativity, turning each plate into a canvas for personalized markings. The journey from Engraved Device Covers to this innovative approach signifies a commitment to pushing identification and customization boundaries.

Many Payment Options, Singular Satisfaction.

In industrial and manufacturing settings, the transition to Paint Filled Stainless Plates is a pivotal moment. Laser Engraving, with a rich history dating back to 1891, has evolved into a versatile and indispensable technology. This evolution meets the demands of practical identification and introduces a creative dimension, turning stainless plates into unique functional art pieces.

Do you need Paint Filled Stainless Plates?

Got A Project?

(800) 482-1553

Monday – Friday – 9:00 am – 5:00 pm