When it comes to efficiency and design, even the smallest details can make a significant impact. And so the different engraving techniques for switch plate covers can make a difference.

Ok, so switch plate covers may seem like a mundane element of decor and organization. But, they are important aspects in many industries and companies.

Engraved switch plates, in particular, bring efficiency, safety, and increased productivity.

At Engraved Switch Plates Now, we have over 130 years in this industry. We specialize in providing high-quality engraved switch plate covers tailored to our client’s preferences.

Here’s a quick overview to start us off, and then we’ll get into more details.

Switch plate covers offer a canvas for engraving design. Techniques like traditional engraving, laser engraving, and chemical etching are primary options. Avoid pitfalls like poor materials and unreliable sellers when ordering online. Engraving companies ensure expertise, quality, and customization.

So what are the different engraving techniques for switch plate covers? Our comprehensive guide will delve deeply into the topic.

We’ll outline the various engraving techniques, methods, equipment requirements, and the advantages and disadvantages of each approach.

Engraving Techniques for Switch Plate Covers

To get straight into the main part of our guide, we’ll explore each of the three primary engraving techniques for switch plate covers. Let’s begin with the traditional engraving technique.

Traditional Engraving

Traditional engraving involves using sharp tools, such as gravers or burins, to carve designs into metal switch plates.

For us, this method requires a high level of skill and precision, making it ideal for intricate patterns and detailed artwork.

Despite being difficult, traditional engraving imparts a timeless aesthetic. With skill, it can produce crisp, clean lines that enhance the overall elegance of the switch plate cover.

Laser Engraving

Laser engraving uses a focused beam of light to ‘etch’ designs onto the surface of switch plate covers.

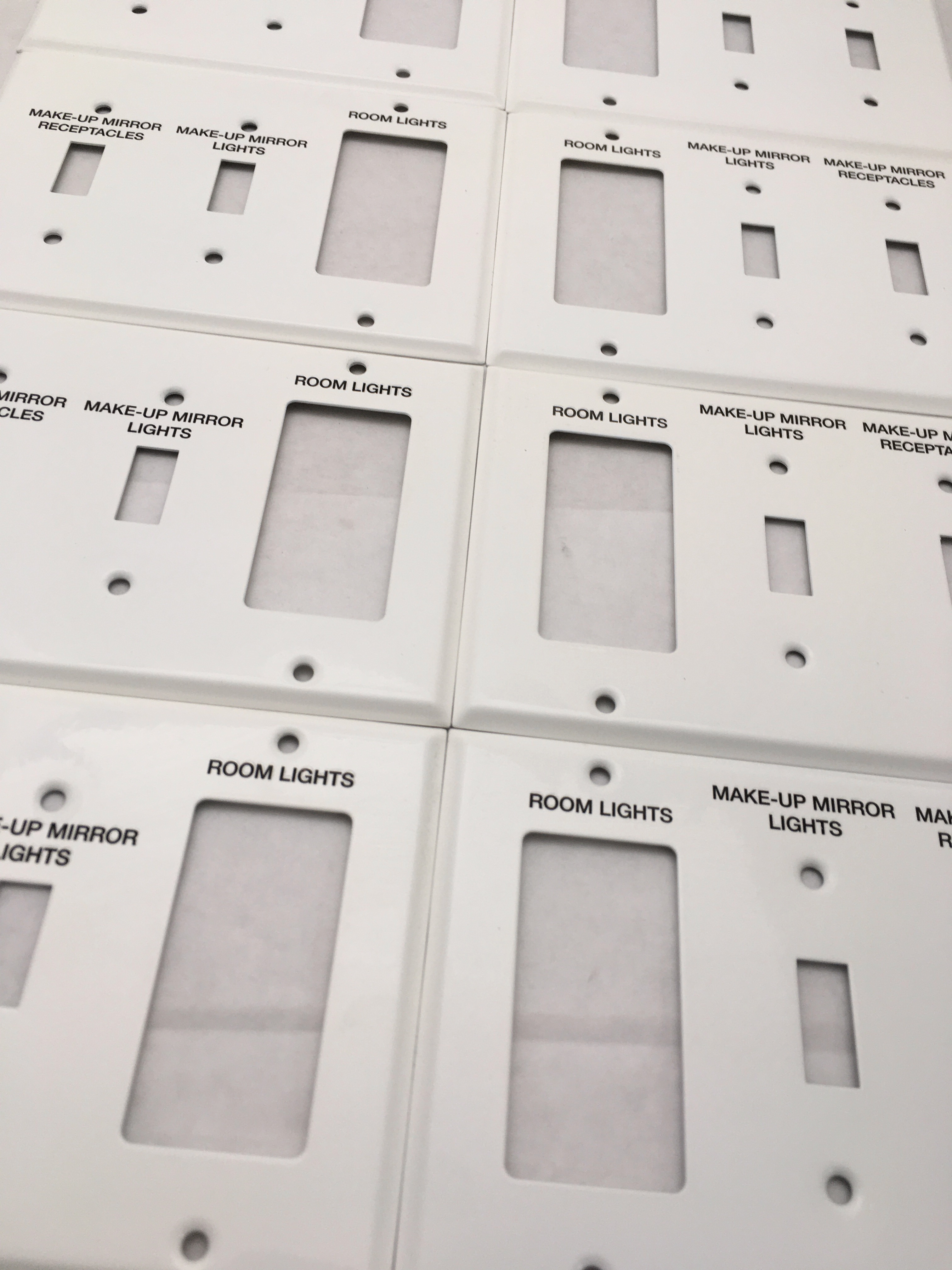

This method offers unparalleled precision and versatility, allowing for the reproduction of intricate designs with intricate detail.

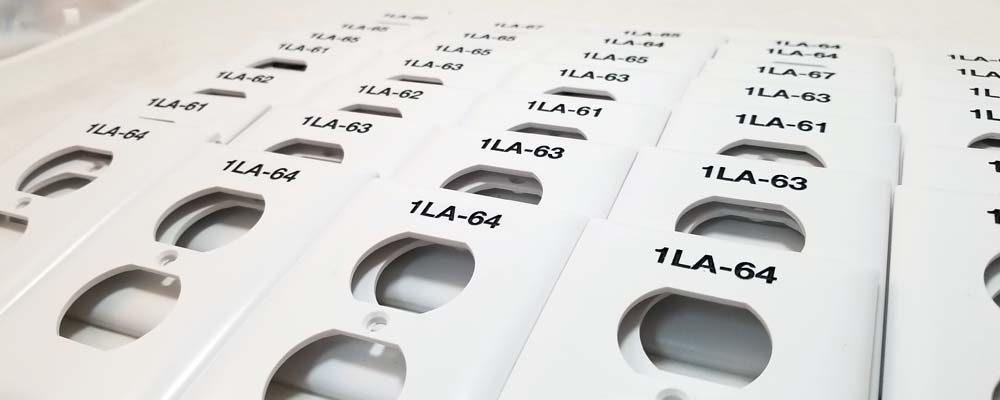

Laser engraving is particularly well-suited for complex artwork, logos, and text. It also enables customization on various materials, including metal, plastic, and wood.

This method also enables us to engrave switch plate covers in bulk. Contact us for this service.

Chemical Etching

Chemical etching involves using chemical solutions to selectively remove material from the surface of switch plate covers, creating raised or recessed designs.

This method offers excellent control over the depth and intricacy of the engraving, resulting in finely detailed and tactile switch plate covers.

Chemical etching can be effective for producing tactile textures and three-dimensional designs.

Equipment Requirements for Engraving

Traditional Engraving

Traditional engraving is highly skilled, so it requires specialized tools, including hand tools like gravers, burins, engraving machines, and magnification devices to ensure precision and accuracy.

Laser Engraving

Laser engraving is a specialism for our company. It necessitates a laser engraving machine equipped with the appropriate software for design customization and control.

Additionally, safety precautions, such as protective eyewear and ventilation systems, are essential when operating laser engraving equipment.

Chemical Etching

Chemical etching requires chemical solutions, such as acids or etchants, along with masking materials and protective gear to ensure safety during the etching process.

It achieves what you need, but it’s a messy business, it needs specialist regulatory permissions, and it can prove costly unless it’s for bulk purposes.

We’ve touched on a few pros and cons already, but let’s expand on that next to give you a balanced view.

Engraving Techniques – Pros and Cons

Traditional Engraving

Pros: Offers skilled precision and detail, produces crisp and clean lines, and imparts a timeless aesthetic.

Cons: Requires a high level of skill and expertise, time-consuming process, increased error rate, and limited scalability for mass production.

Laser Engraving

Pros: Provides exceptional precision and versatility, enables customization on various materials, and is efficient and cost-effective for bulk production.

Cons: Initial investment in equipment can be expensive, and requires technical training and ideally experience in operation and maintenance.

Chemical Etching

Pros: Allows for intricate designs and tactile textures, suitable for producing three-dimensional effects, and is relatively cost-effective for small-scale production.

Cons: Requires careful handling of chemical solutions, potential environmental and safety hazards, limited to certain materials.

So unless you plan on becoming a skilled engraver and crafting your expertise over several years, or perhaps working with engraving chemicals… or maybe purchasing expensive laser equipment, you may want to look at easier and better options.

Why Choose an Engraved Switch Plate Company

When selecting the right engraving techniques for switch plate covers, while some may attempt DIY engraving projects, most clients prefer to entrust their switch plate customization to a professional engraving company like Engraved Switch Plates Now.

Here’s Why:

- Expertise and Experience: Engraving companies like ours have the knowledge, skills, and experience to execute intricate designs precisely and accurately.

- Quality Assurance: Engraving companies use high-quality materials and state-of-the-art equipment to ensure superior craftsmanship and durability.

- Customization Options: We offer various customization options, including design selection, material choice, and finish preferences, to suit each client’s unique requirements.

- Convenience and Efficiency: Engraving companies like ours streamline the ordering process, from design consultation to production and delivery, ensuring a seamless experience for clients.

With that final point in mind, here’s our simple guide to placing your order – we’ve made ordering engraved switch plate covers much easier than trying to engrave them yourself with hand tools!

How to Order:

Ordering customized switch plate covers from EngravedSwitchPlatesNow.com is a straightforward process:

- Design Consultation: Contact our team to discuss your design ideas, preferences, and specifications for your switch plate covers. Or simply request a quote or even ask for a sample switch plate.

- Design Approval: Review and approve the digital mockup of your customized switch plate covers before production begins.

- Production: Our skilled technicians will meticulously engrave your switch plate covers using the chosen technique and materials.

- Quality Inspection: Each switch plate cover undergoes rigorous quality inspection to ensure adherence to our high standards of craftsmanship.

- Delivery: Your custom switch plate covers will be carefully packaged and shipped to your desired location, ready to enhance your space with personalized elegance.

We also deal with larger bulk orders – just contact us here.

What to Avoid When Ordering Switch Plates Online:

When ordering switch plates online, it’s essential to avoid common pitfalls to ensure a satisfactory experience:

- Lack of Customization: Beware of websites that offer limited customization options or pre-made designs, as they may not meet your specific preferences and requirements.

- Poor Quality Materials: Avoid purchasing switch plates made from low-quality materials, as they may be prone to damage and wear more quickly over time.

- Unreliable Sellers: Choose reputable and trustworthy sellers with positive reviews and a track record of delivering high-quality products and exceptional customer service.

- Inaccurate Sizing: Ensure accurate measurements of your switch plate dimensions to avoid ordering covers that are too small or too large for your outlets and switches.

Follow these guidelines and partner with a reputable engraving company like Engraved Switch Plates Now.

With us, you can enjoy customized switch plate covers that elevate the aesthetic appeal of your manufacturing plant, office space, or government underground bunker!

That’s the different engraving techniques for switch plate covers. So let’s round this topic up.

Different Engraving Techniques for Switch Plate Covers

The different engraving techniques for switch plate covers offer a range of possibilities for personalization and enhancement in interior design.

Engraving companies provide expertise, quality assurance, and seamless customization processes, ensuring satisfaction for every client.

When ordering online, it’s crucial to navigate carefully, avoiding pitfalls such as poor materials and unreliable sellers. We hope this has answered the question; ‘What are the different engraving techniques for switch plate covers.’

Contact us today to begin the journey towards personalized elegance and sophistication.

Comments are closed