Why Label Device Covers?

Why Label Device Covers? When making modifications or troubleshooting a problem, it is important to identify the power outlets. The outlet box generally contains many cords including coaxial, cat 5, or fiber-optic cables for televisions, telephones, video, audio, and broadband connections. It can become overwhelming when you have hundreds of outlets.

Why Label Device Covers? Because Outlets Fail

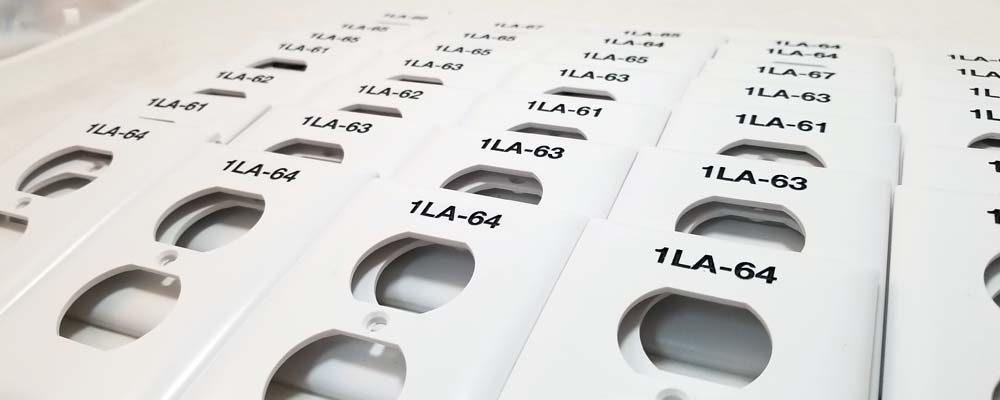

In the event that you require an outlet to be activated or have a problem with an existing outlet, you will need the face plate number when you call for assistance. Each connection may have its own number or one number covering all the connections. Therefore, the number on each face plate or outlet is unique.

Make Fixing Failures Quicker than Ever

It becomes difficult for the user to properly identify an outlet if the face plate is missing the label, or if the label is damaged or difficult to read. Many times you are stuck trying to make out someones rushed scribbles with a dry marker and it is a big waste of time, not to mention dangerous. Support will be unable to repair the outlet if this occurs. Having outlets labeled allows you to save time and money in getting it located and repaired!

Why Label Device Covers? Don’t Get Wiped Off the Map!

Often times during deep cleaning, the staff may use harsh cleaners to clean and wipe the face plates. As a result of this cleaning, the label on the plate may be smudged, removed, or the corner of the label may lift over time. Once the corner is lifted, the label becomes more susceptible to removal, resulting in a more difficult time identifying it for repair. The material of the face plate will more than likely withstand repeated deep cleanings without becoming damaged. It is common for some printers to have a device built in to trim the corners of the label, thereby making them more resistant to corner peeling.

Resists Damage

As a result, if the faceplate is located in a high traffic area, these issues are further exacerbated. Depending on the number of face plate labels required and the speed at which you need them, you may wonder what’s the best way to tackle the job. Installers may prefer the use of a portable printer to print and install labels as they work through a job. Others may prefer to print a continuous strip of labels. If the job requires repeats, sequences, or barcodes, printers can sometimes be configured accordingly.

Why Label Device Covers? Lasers!

Why add extra steps and multiple times fixing an issue there is already a perfect solution to? LASER ENGRAVING, One and Done! No need to keep buying expensive labels and label makers, and pay someone each time to replace them. We can engrave and paint fill face plates that will outlast all those options. They can withstand cleaning and harsh environments and high traffic area.Could there be a more perfect answer? Save time and money and above all, maintain a safe and secure system at all times.

Why Traditional Labels Fail and Ultimately Cost More Long Term

- Incompatible Temperatures – If Temperatures fluctuate in the air and/or surface can also contribute to label failure. If the compatible label and adhesive are not combined, the label will not expand and contract with the air and surface which may result in Faded and cracked label, time to replace (yet again, more wasted time and money).

- Conflicting Surface Material – The best suited surface for label adhesion is clean and dry, and smooth if possible. If the surface cannot be properly prepared for adhesion, the label will need additional steps. (More wasted time and money.)

- Adhesive Breakdown – Adhesives that binds the paper part of the label to the surface you are labeling. An adhesives durability will vary due to many factors such as temperature, surface preparation or UV rays to name a few.

- Other Variables – Such as Lack of UV protection when exposed to the sun and low quality labels. Adhesives sometimes require pressure to create a bond with the surface (that equals real human time to achieve for each label.)

Save Money with Laser.US, Industry Leader of 135 Years

Don’t get sucked into the idea that other companies meet our standards, because we’ve set the standards for 135 years–that’s five generations! Once you factor in replacing cheaper labels, and the cost of paying someone to do so, let alone what can happen when these fail to hold up to cleaning and leave you paying four times the amount to fix a broken outlet? And the fact our prices are lower than other companies with less than 20 years in the business? You’ll see we’re a, and the, real deal!

Comments are closed