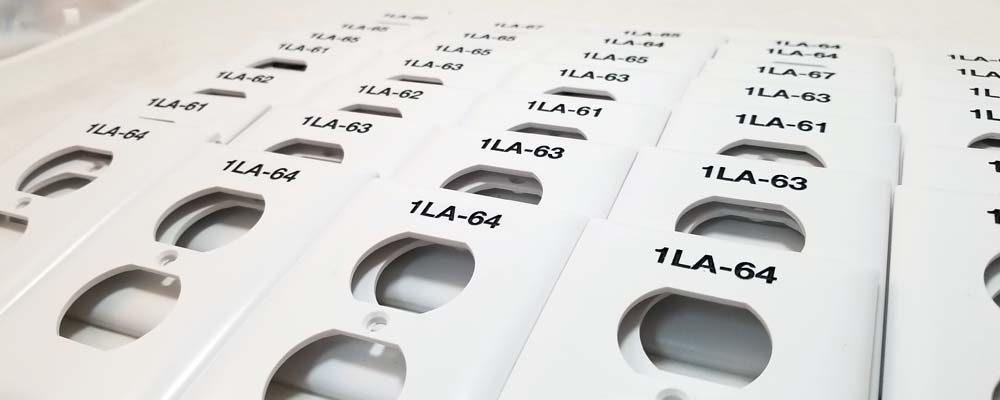

Engraved Nylon Wall Plates

Ever walked into a building and noticed Nylon wall plates or receptacle covers with distinct, permanent markings? It’s highly likely that these markings were laser-engraved directly onto the metal or plastic cover plates. Laser engraving has become the industry norm for permanently marking receptacle covers, ensuring enduring visibility of each receptacle identification and streamlining installation for both electricians and electrical inspectors.

Low Voltage Switches & Plates – Push Button Switches & Plates

The laser engraving process utilizes a high-powered laser beam to etch patterns into various materials, including stainless steel, metal, nylon, and plastic. Beyond etching patterns, the laser beam can also paint-fill circuit numbers and panel numbers onto the plate’s surface, guaranteeing legible and enduring identification. Laser engraving enables a level of detail and customization that is challenging to achieve with traditional methods. The ability to engrave variable data directly onto the material provides a tailored solution for specific project requirements. Whether it’s circuit numbers, panel numbers, or other identifiers, laser engraving offers a high degree of customization.

As technology continues to advance, laser engraving techniques are likely to evolve further. Innovations may include enhanced speed, increased material compatibility, and additional features that push the boundaries of what is currently achievable. Staying abreast of these advancements can be crucial for industries relying on laser engraving for identification purposes.

Check out our FABRICATION SERVICES websites take on SWITCH PLATES !

In conclusion, laser engraving for receptacle covers emerges as a multifaceted solution that combines precision, durability, cost-effectiveness, and efficiency. Its applications extend across various industries, offering benefits that address both practical and environmental considerations. The continued evolution of laser engraving technology is expected to bring even more sophisticated solutions to the realm of permanent identification. Electricians and electrical inspectors benefit significantly from the efficiency brought about by laser engraving Nylon Wall Plates. The clear and legible markings simplify the installation process, allowing for quick and accurate identification of receptacles. This efficiency not only saves time during installation but also contributes to overall project timelines.

This technology has transformed the way we identify receptacle covers in both government buildings and private homes. No longer reliant on labels or decals that may fade or be removed due to wear and tear or deep cleanings, laser engraving allows for the direct engraving of variable data into the material itself. In the context of sustainability, laser engraving can be viewed favorably. The permanence of the markings reduces the need for disposable labels or decals, contributing to a reduction in waste. Additionally, the efficiency of the laser engraving process, with minimal manual labor and material waste, aligns with environmentally conscious practices.

Get another opinion on DEVICE COVERS!

Laser engraving boasts numerous advantages over traditional methods like labeling or decaling. It proves cost-effective in the long run, eliminating the need for periodic label replacement, and provides an exceptionally durable solution that withstands the test of time. Additionally, laser engraving ensures heightened accuracy as each piece is individually marked with precise measurements and exact specifications. Lastly, it expedites the process with a much faster turnaround, as there is no requirement for manual labor – simply point, shoot, and repeat!

Do you need Engraved Nylon Wall Plates ?

While laser engraving may involve upfront costs for equipment and technology, it proves to be a cost-effective solution in the long run. Traditional methods, like labels, often require periodic replacement, incurring ongoing expenses. Laser-engraved markings, on the other hand, eliminate the need for such replacements, resulting in long-term savings. One of the primary benefits of laser engraving is the creation of permanent and enduring markings. Unlike labels or decals that may degrade over time due to wear, tear, or cleaning, laser-engraved identifications remain intact, providing a long-lasting solution. This is particularly crucial in environments where the durability of markings is paramount, such as industrial settings or high-traffic areas.

Direct Shipping, Easy Ordering

Engraving stainless steel, metal, nylon, and plastic receptacle covers with lasers offers an efficient means of marking these items with variable data while ensuring their longevity. This method not only saves costs by obviating the need for periodic label replacement but also enhances accuracy due to its precise measurement of each piece. Fundamentally, laser engraving provides an enduring and detailed solution that facilitates installation for electricians, surpassing traditional labeling methods – making it an indispensable tool in any electrical project! Whether seeking a swift solution or something more permanent, laser engraving is the answer!

Switch Plate Engraving is our Specialty.

CONTACT US NOW!

Talk to our LIVE HUMANS!

(800) 482 -1553

Mon – Fri 9AM – 5PM EST

Visit Our Sister Sites!

Laser.us

LaserEngravingPros.com

Metaltagmaker.com

Lasercuttingpros.net

EngravingTumblers.com