Engraving on stainless steel device covers means carving designs or words onto the surfaces of covers like those on light switches or equipment panels. While it’s a cool way to make these items unique, showing off your company’s logo or specific information like room numbers or equipment settings, it’s also important for health and safety.

Engraving Stainless Device Covers Help Ditch The Danger With Device Cover Engraving

Some devices could be dangerous if handled incorrectly, or cause harm if operated without knowledge of what it controls. By engraving critical information to the device cover, you can reduce the risk of injury within both residential and commercial settings.

Since engraving stainless device covers is our specialty, we have a fool-proof process to ensure our clients are satisfied with their engraving every time.

So, let’s talk about why we will always choose to work with you directly when it comes to engraving stainless device covers.

Engraving Stainless Device Covers and Our Process

Adding an engraving to a device cover can definitely make it safer, especially for those who need to use the device. But it can also help it to look more bespoke, professional, and stylish. Engraving involves a detailed process, which our experts have effectively simplified in the following way;

1: Submit Your Brief & Data To Our Team

To kick off our engraving stainless device cover process, you’ll first need to provide our team with the necessary data to complete the work. Generally, this information can be sent to us via spreadsheet and should include the details of each engraving you require.

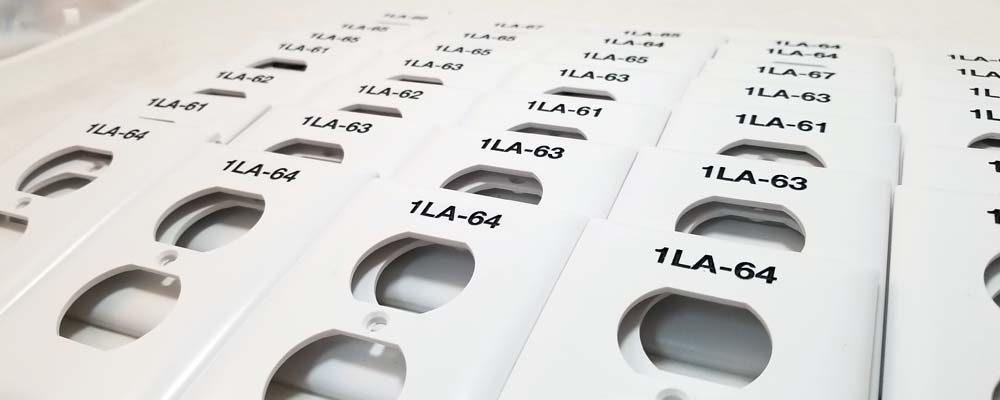

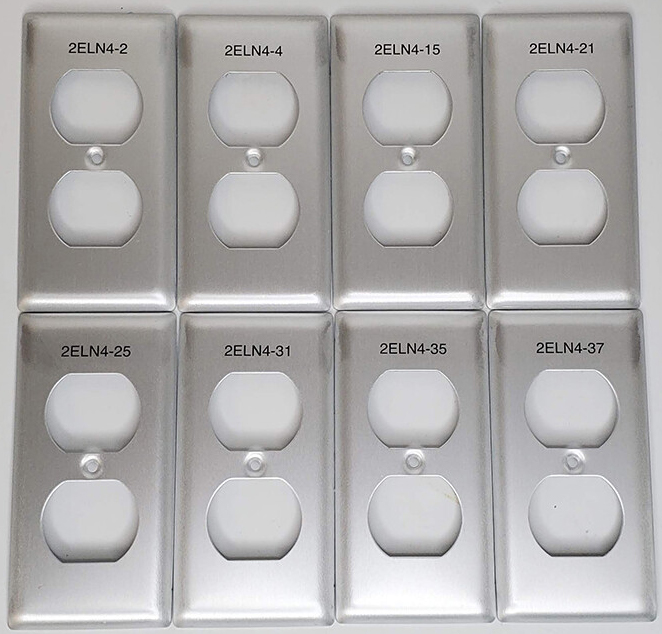

Depending on your unique project, this might include serial numbers, labels, or codes. By having a spreadsheet to refer back to, our team will know exactly what you need on each device, eliminating any room for errors or miscommunication.

2: Our Engraving Techniques

When it comes to customizing stainless steel device covers, there are a number of engraving techniques we can choose from.

Most of the time, we are asked to provide advanced laser engraving technology to etch details deep into the metal, ensuring longevity and resistance to wear and tear. This method allows for precision and versatility in designs, accommodating varying depths and complexities. We can discuss your unique requirements during a quick consultation call at this stage.

3: Paintfill Application For Extended Lifespan

Not only does this give the final design a more professional and clean finish, but it also helps to protect the engravement against environmental factors such as dirt, debris, and changes in humidity and temperature.

Each post-engraving device cover we complete is treated with two coats of high-quality enamel paint fill. This means it will stand the test of time. So once the information has been added to the device cover, it’s going to stay there for many years to come. This is a significant ROI for such a small upfront fee.

4:Custom Packaging and Shipping

We understand and appreciate that you will have unique needs as a customer, and so we will offer you customizable packing and shipping options. Whether it’s bulk shipping or individual packaging, we adapt to your specifications to ensure safe and efficient delivery.

5: Supply Flexibility

You can even send us your own device covers or have us provide them for you. This gives you more flexibility when it comes to placing an order with us. For those opting for the latter, simply inform us of the brand and part numbers, and we will handle the rest.

What Type Of Stainless Device or Surface Can We Engrave?

If you’re not sure whether the stainless device plate you have can be engraved by our team, don’t worry. Below we’ve outlined the wide range of stainless device plates that can be made bespoke with our professional engravement techniques.

Engraving Stainless Device Covers Switch Plates

Most commonly found in residential and commercial buildings, engraving switch plates can include labeling light switches, power outlets, and other controls. This is particularly useful in complex setups like home theaters or conference rooms. Why engrave a switch plate? Well, it helps to identify what the switch is able to control. For example a light for an attic or automatic blinds within a conference room.

Control Panels

Within an industrial setting, control panels operate machinery, and systems often need to be engraved to make sure their purpose is easy to understand. This additional safety feature helps to reduce operational errors and enhance safety overall.

Door Plates

To direct post and packages to the right address, engraved door plates are used in offices, hotels, and other public buildings. They can also be used to display office titles or employee names, such as in a doctor’s office.

Informational Signage

This includes signs for bathrooms, emergency exits, informational guides, and directories. Stainless steel is durable and resistant to corrosion, making it ideal for both indoor and outdoor signage.

Engraving Stainless Device Covers Barcode Plates

Used extensively in logistics and warehousing, barcode plates are engraved to make tracking inventory and equipment easier than ever.

Medical Equipment Tags

Within the healthcare industry, stainless steel plates and polyester tags can be engraved or printed with critical information about the equipment, such as usage instructions, sterilization dates, and tracking IDs. The non-porous nature of stainless steel makes it hygienic for such environments.

Book A Consultation For Stainless Device Engraving

We understand the importance of ensuring that every detail meets your exact specifications, which is why we offer direct consultations as part of our service. During these consultations, we collaborate closely with you to develop and refine sample plates.

These prototypes serve as a concrete preview of the final product, allowing both you and your team to assess the design, text, and overall look before full-scale production begins.

Engraving Stainless Device Covers Bulk Order Sign-Off Request

It’s common for project managers to require formal approval from their clients before moving forward with large orders. This step is crucial because it ensures that all parties are aligned with the design choices and quality expectations. By reviewing and approving these physical samples, you can avoid any miscommunications or errors that might otherwise occur when producing large quantities of engraved device covers.

Our goal is to make this approval process as smooth and efficient as possible. We will ensure that once you give the green light, we can proceed with confidence, knowing that the final products will meet your expectations and those of your clients. This careful attention to pre-production details helps streamline the entire process, from initial design to final delivery.

Request A Complimentary Stainless Steel Engraving Sample

We offer samples shipped to you at no charge or hassle. You don’t have to worry about generating a PO or getting approval. To make a buy just for some sample parts.

We cut through all of the red tape to ensure that your plates are engraved and painted-filled promptly and, most importantly, that you’re satisfied!

Comments are closed