Choosing the Right Switchplate

Thermosets vs Thermoplastic: Have you ever looked at a Plastic Outlet Cover and said to yourself, “Hey, what’s the deal with this thing?” Well, worry no more! We’re here to give you the lowdown on Our Plastic Outlet Covers made of Thermoplastic Nylon and how they compare to other types of plastics as well as metal outlet covers. Let’s explore why these are not only the best choice for Laser Engraved and Paint-Filled Outlet Covers and Switchplates, but also why they offer a number of advantages over other Plastics known as Thermosetting Plastics and metals such as Stainless Steel

For Starters, Thermoplastic Nylon Plastic Outlet Covers are incredibly lightweight yet strong enough to withstand heavy wear-and-tear. Thermoplastic Nylon has both amorphous and crystalline microstructures when cooled, which is a fancy way to stay the material gains elasticity as well as rigidity and stiffness after it is heated and then cooled. Additionally, Nylon Switchplates can be Custom Painted in almost any color imaginable, making them great for branding purposes.

Both Thermosets and Thermoplastics are types of plastic, but each offers different advantages and disadvantages. His blog post will discuss why Thermoplastic Nylon Plastic Outlet Covers are an excellent choice for hospitals, federal buildings, government offices, schools, and universities- all because Nylon is Thermoplastic! Let’s dive into the argument: Why are our Thermoplastic Nylon Plastic Outlet Covers such an excellent option for high-traffic, sanitary areas such as Hospitals? What makes plastic a better choice for outlet covers, wall plates, and switchplates than metals like stainless steel?

What Is Thermoplastic Nylon?

There are quite a few materials that are considered Thermoplastics, including Nylon, Acrylic, Teflon, and many more. Thermoplastic is a type of plastic that becomes malleable when heated but returns to its original state when cooled. Thermoplastics can be melted down & reshaped multiple times without losing their physical properties. They do not form chemical bonds when curing, making them remouldable, recyclable, sustainable, and “green,” unlike Thermoset Plastics, which form chemical bonds when they cure. Thermosets are not recyclable or sustainable.

The unique characteristics of Thermoplastics make Nylon an ideal material for Laser Engraving Plastic Outlet Covers, as we can precisely control the temperature of the Engraving process and mold the material into any shape or size. Thermoplastic Nylon is lightweight, yet strong enough to withstand the rigors of Cover Plate Engraving and Paint-Filling. Also, it has excellent electrical insulation properties making it well-suited for use in electrical applications such as Plastic Outlet Covers.

Restricted Access

Thermoplastic Nylon is exceptionally durable and able to withstand extreme temperatures (-60°F to 300°F) without cracking or fading and is resistant against heat, oil, abrasion, and chemicals. Nylon is resistant to fire – UL 94V0 rated – perfect for use in high-traffic areas such as federal buildings, government offices, courthouses, schools, and universities! Thermoplastic is also non-porous; It’s easy to clean and disinfect, making it an excellent choice for sterile medical facilities and hospitals as well! So if you’re looking for a material that is highly durable, easy to clean, and can be Laser Engraved with precision, Thermoplastic Nylon is the way to go for your Plastic Outlet Covers project!

Comparison to Other Materials

Thermoplastic Nylon offers some clear advantages compared to other materials, such as Thermoset Plastic, Stainless Steel, and other metal Outlet Covers. Thermoset Plastic Outlet Covers are generally cheaper than Thermoplastics but lack their durability; they often crack when subjected to extreme temperatures, vibrations, or pressure. Stainless Steel Switchplates may be more durable than Thermoplastic Nylon and Thermoset Plastic. Still, the higher cost of Stainless prevents it from being used in many applications. Stainless Steel plates are great but much more expensive to Customize, Paint, or Engrave; Thermoplastics such as Nylon allow for much more affordable yet precise Engraving and Paint-Filling options.

What about Thermoset Plastics? Thermosets vs Thermoplastics

In contrast to Thermoplastics, Thermoset Plastics cannot be melted or reformed after their initial molding process. This makes Thermoset Plastics less ideal for specific applications such as Laser Engraving or Paint Filling Plastic Outlet Covers because these processes require heat, damaging the material. Thermoset Plastic Switchplates are less durable than those made from Nylon because they have different impact resistance qualities. Because they form chemical bonds when they cure and their chemical composition changes permanently after heating, Thermoset Plastic cannot be remoulded and is much less heat-resistant. They are also quite challenging to surface finish compared to Thermoplastics.

How Does Stainless Steel Compare?

Stainless Steel is another material we use to create Switchplates; However, it is more expensive than either Thermoplastic or Thermoset Plastic and has more limited customization capabilities due to its hardness and must be Engraved with state-of-the-art equipment like our giant lasers here at Laser Engraving Pros.

Stainless Steel Outlet Covers offer less protection against electric shocks due to their very high conductibility, especially when compared to either type of Plastic Outlet Covers, making Stainless an inferior choice for electrical applications in particular, such as Outlet Covers. Laser Engraving Stainless can also lead to corruption over time, so Engraved Stainless Steel is not a good choice for outdoor or long-term applications, like in the case of Switchplates and Outlet Covers.

High Voltage Warning

This is because Laser Engraving Stainless removes an essential protective layer of the metal: The “Stainless” part of “Stainless Steel.” In fact, any method whatsoever that digs markings on the surface (deep or shallow), such as Laser Engraving, will remove this thin protective layer composed of Chromium Oxide. That is why many of our Engraved metal products are Anodized. In other words, we finish them with a protective layer of Anodic Oxide, which is durable and corrosion-resistant as well as Decorative. But Anodization involves more materials, equipment, and time, adding cost to the final product.

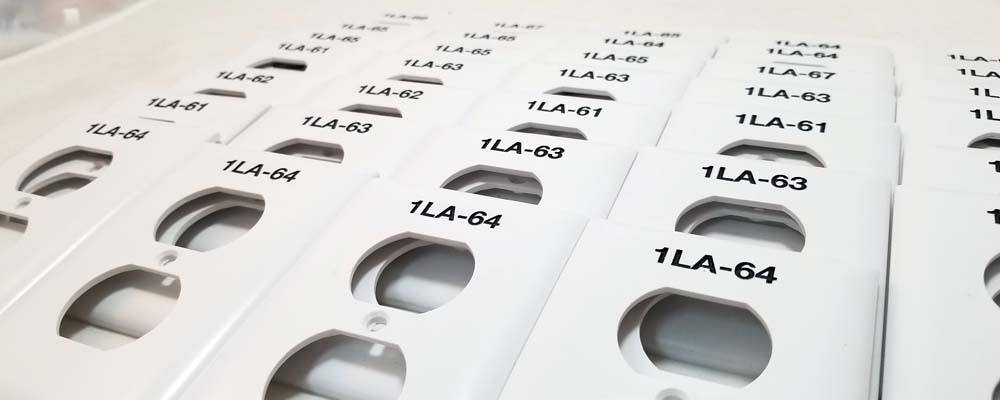

Seeing it IS Believing

When fabricating Plastic Outlet Covers for Hospitals, Federal Buildings, Government Offices, Schools, and Universities, there’s no better choice than our Nylon Plastic Outlet Covers! With its lightweight yet strong structure and excellent electrical insulation properties, you can rest assured that your Custom

Engraved Switchplate will hold up under any conditions while providing exceptional protection against electric shocks due to its ability to resist heat and temperature changes better than other materials like Stainless Steel or Thermoset Plastics. So if you’re looking for a durable, easy-to-clean, low-maintenance, affordable, and reliable option with plenty of Customization options, look no further than our range of Custom Engraved Nylon Plastic Outlet Covers!

CONTACT US NOW!

Call us and reach a LIVE PERSON!

(800) 482 – 1553

Mon – Fri. 9AM – 5PM EST

Check out our Sister Sites:

Laser.us

Metaltagmaker.com

Lasercuttingpros.net

Laserengravingpros.com